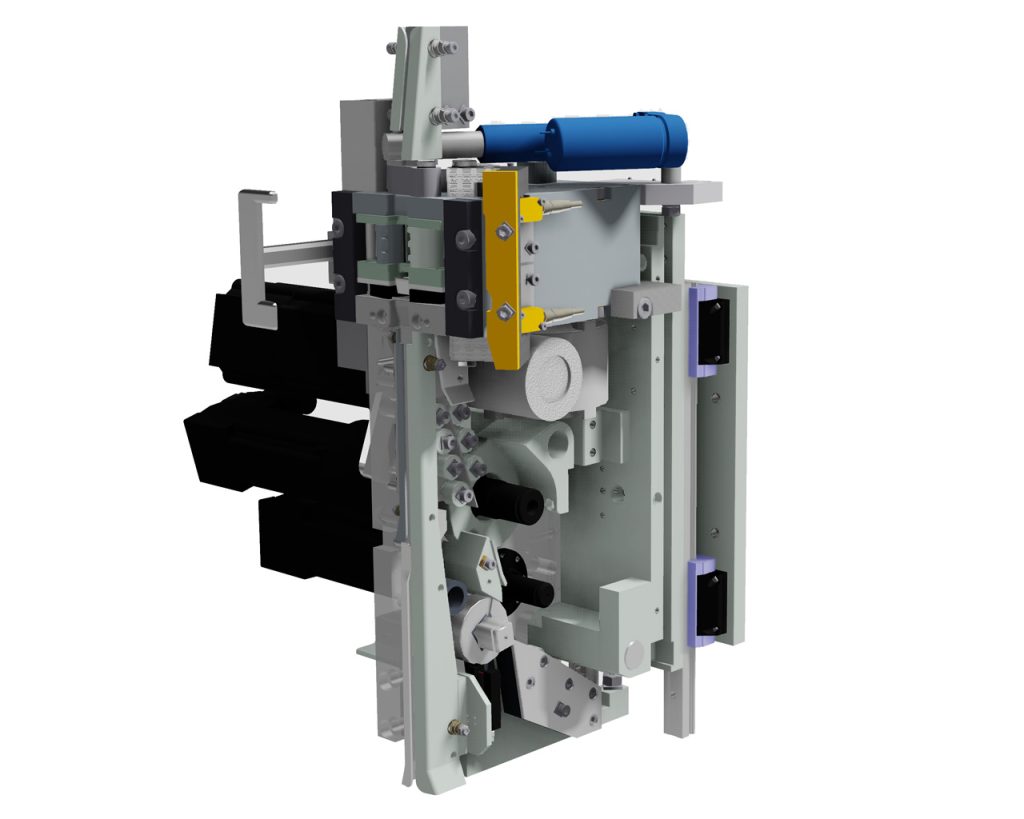

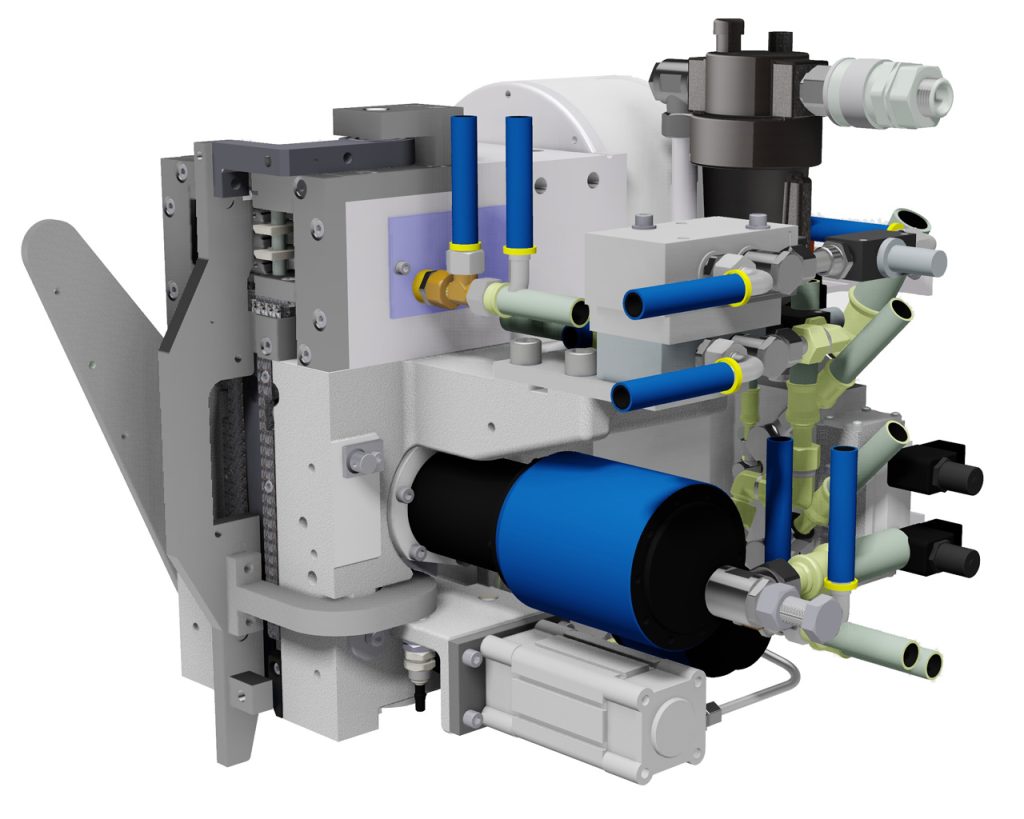

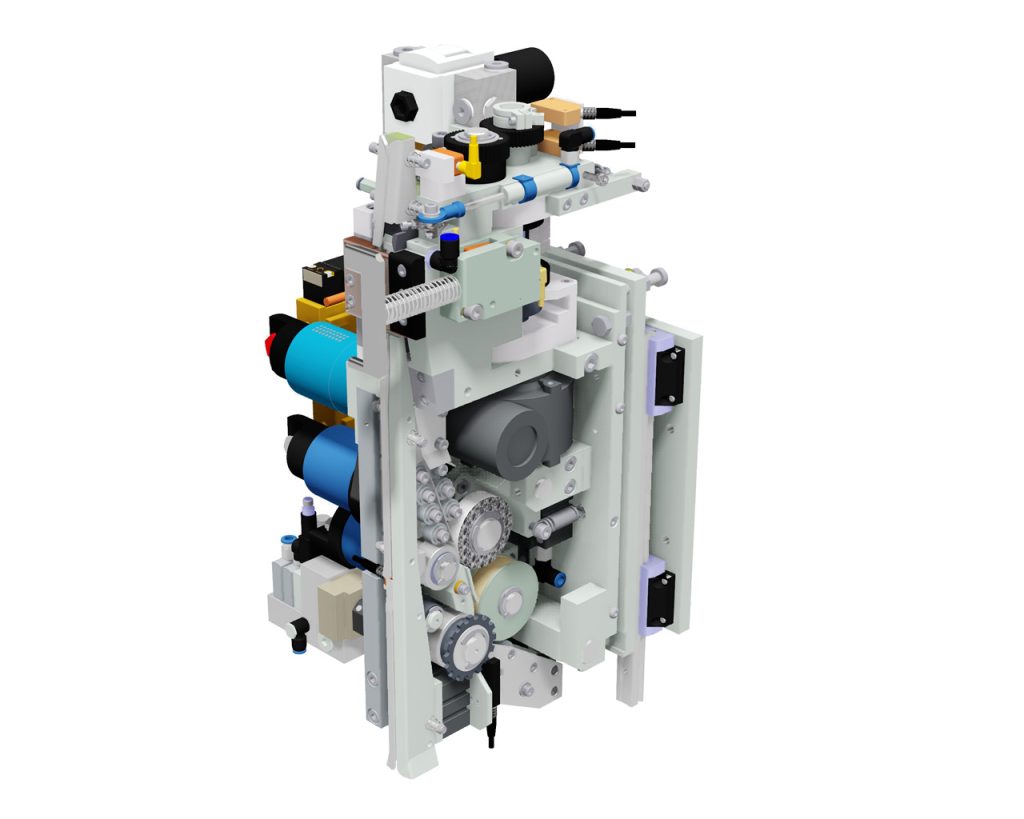

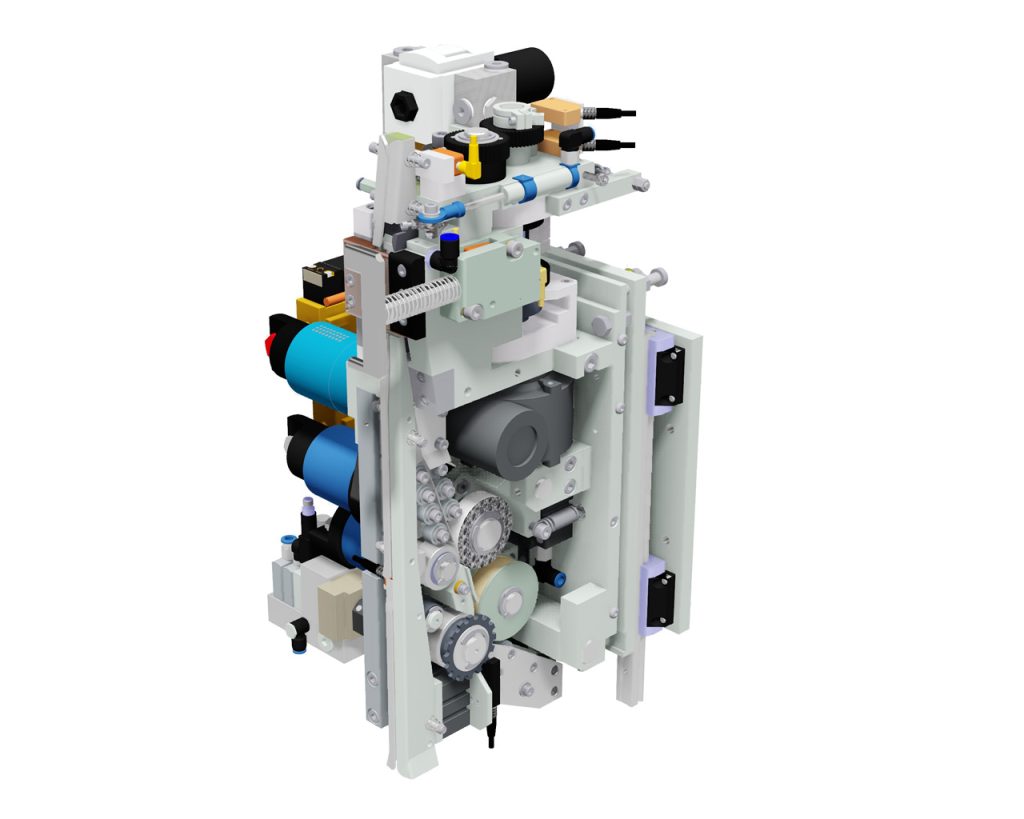

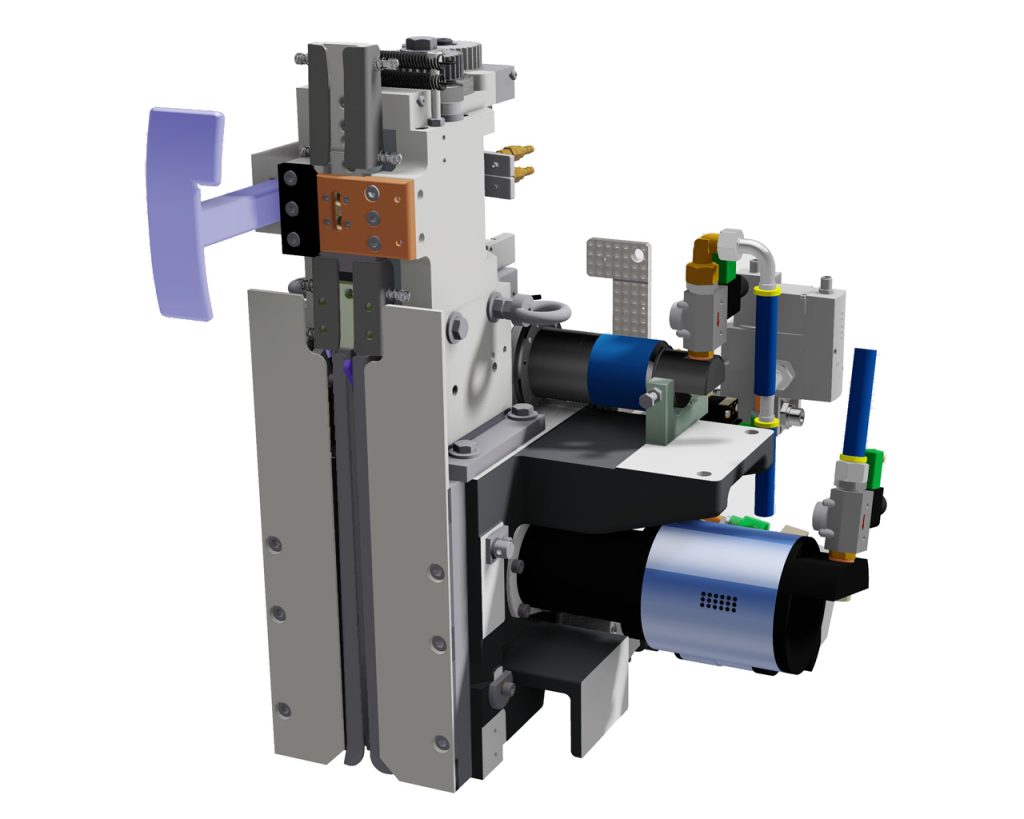

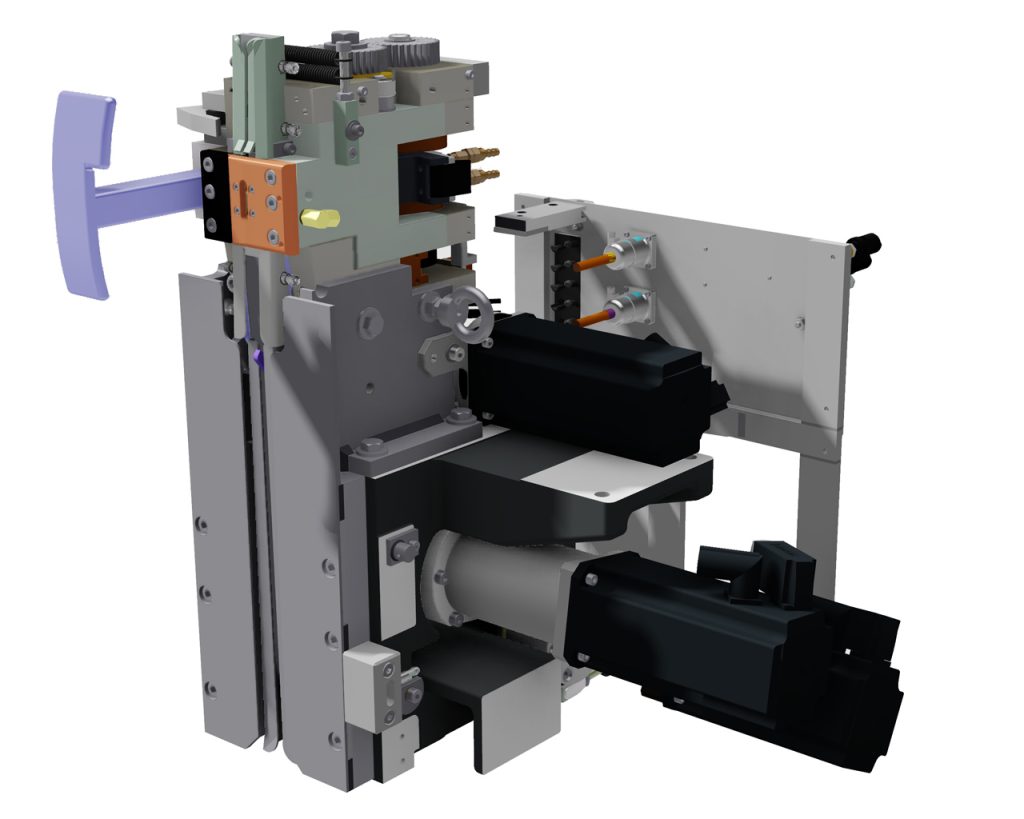

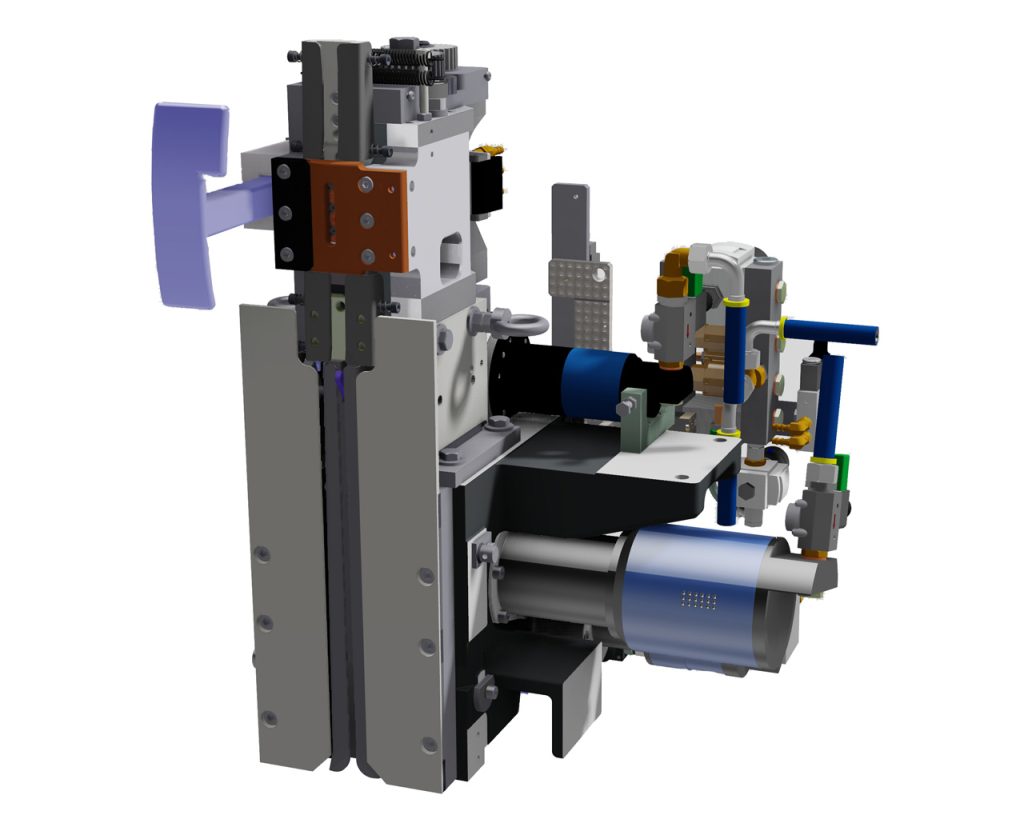

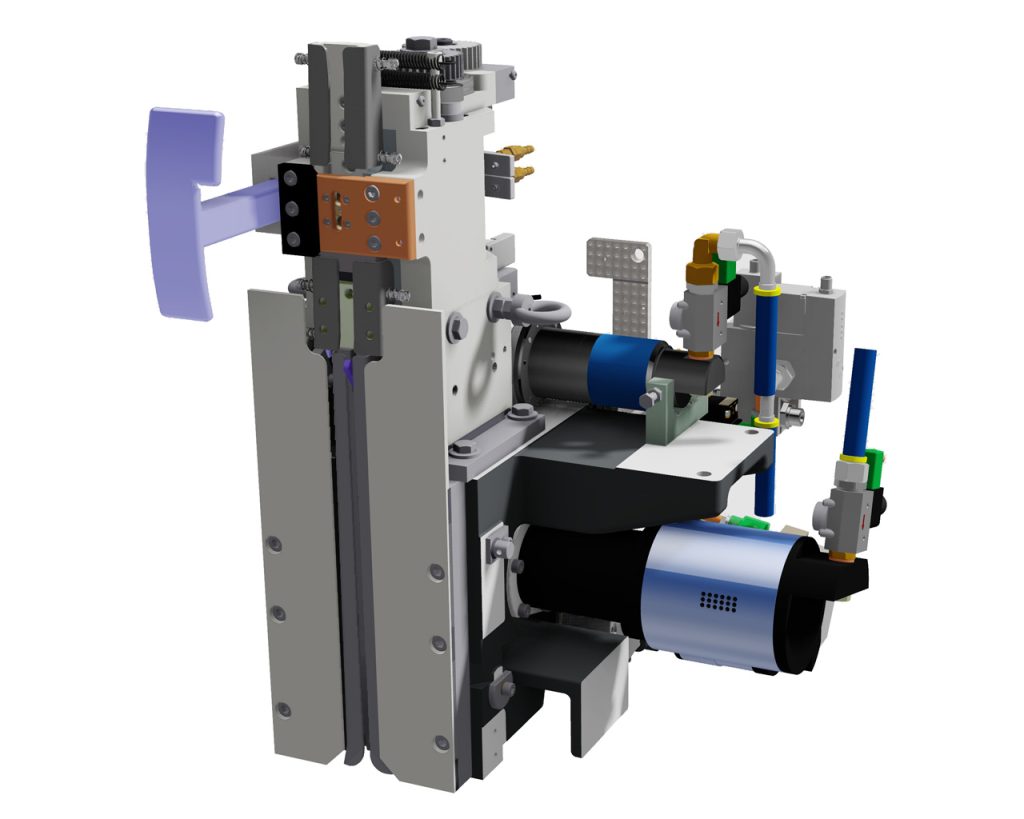

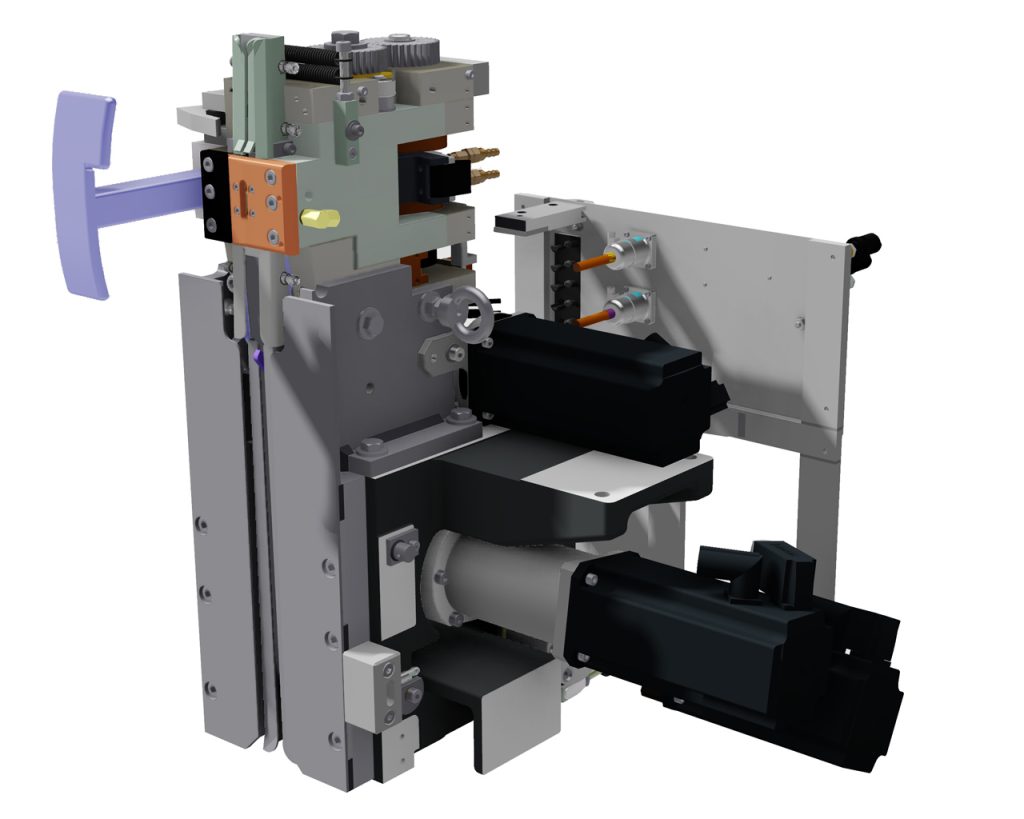

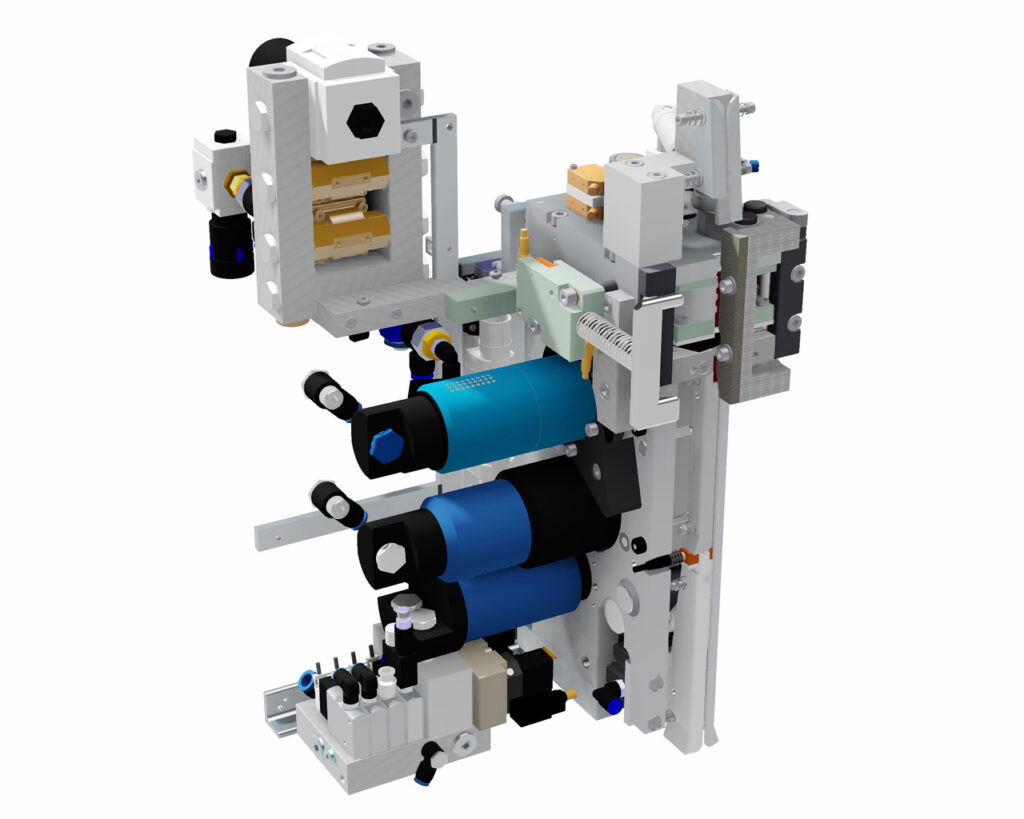

VS11-L

Customer Benefits

• precise control of feeding speed and tension force

• strap straightening unit for trouble-free feeding

• lowest strapping cycle times

Technical Features

• tension force: 1.5 – 10 kN | 337 – 2,250 lbf

• feeding speed: 2.2 m/s | 7.2 ft/sec

• strap dimensions: to 19 x 0.63 mm | 3/4 x 0.025 in